Spider silk is light, airy, and flutters in the wind. Yet beneath its ephemeral surface lies one of the strongest substances on earth. Researchers are fascinated by its mysterious potential. And what it has to do with goats. Goats? A certain goat farm in Quebec requires visitors to shower and put on white coveralls and booties before being allowed to look at the animals. These special goats have been genetically engineered to produce spider silk in their milk. This of course raises the question, why would anyone want a goat to make spider silk? Why spider silk? Spider silk is an amazing material. It can withstand immense stresses in the most adverse of conditions. The next time it rains, look for a spider web. It will likely have many raindrops hanging from it. Look at the size of the raindrops, then look at the width of one strand of the web. The fibre is one-tenth the thickness of a stand of human hair, yet is able to survive environmental stresses such as rain, wind, or a chubby bee flying into it. Spiders have been around for 400 million years and have had that long to perfect their silk-making mechanisms. A paper by Cheryl Hayashi and Randy Lewis, molecular biologists at the University of Wyoming, reported that portions of the silk gene underwent a lot of mutations in evolution. The sections used in coding the silk protein are actually more diverse and mutated than the portions that are not used.

Of the many types of silk that spiders make, dragline silk is the type scientists are most interested in. The main structural frame of a spider web is mainly Dragline silk. It is the non-sticky spokes of the web, whereas capture silk makes up the sticky strands that insects get caught on. A team of scientists led by Catherine Craig of Harvard University's Museum of Comparative Zoology found that the silk produced by spiders also differs according to their diets. The proportion of the components making up the silk differs according to what the spiders ate. Manufactured silk protein will be much more uniform. This is important in industrial manufacturing, where quality and consistency is vital. Spider silk in the past Historically, spider webs have been used by tribal peoples in the South Pacific. They use the webs to make fishing lines and nets. People in Southeast Asia make nets by using a stick bent into a loop to pick up a spider web. Spider webs have also been used to stop bleeding wounds and to make waterproof clothing. In the 1960's, the American military published a report describing the very special properties of spider silk. They studied different spiders, and identified certain ones as having very strong fibres. Twenty years later, modern research into synthetic spider silk really began. "Starting in the late 1980's when all of this genetic engineering technology was invented ... people started thinking 'how can we make structural materials, using genetic engineering and having renewable biodegradable materials,'" says Sam Hudson, a polymer chemist at North Carolina State University's College of Textiles. Hudson studies amalgamations of simpler chemical compounds, known as polymers. The military, biochemical companies, and various academic laboratories then started research, trying to put the spider silk genes into bacteria. Bacteria are often used to make synthetic versions of natural compounds. Many pharmaceuticals are made in bacteria, such as E. coli. But there was a problem. The protein that makes up spider silk is composed mainly of two amino acids, that are essentially building blocks of proteins: alanine and glycine. "The silks are typically about 70 per cent glycine and alanine, which are the two simplest [amino acids]," says Hudson. "And so when you put these spider silk genes into bacteria, basically it strips all the alanine and glycine out of its system to make this protein, and then it doesn't have enough left over to make some enzymes it needs for its living functions, and so the organism dies."

For this reason, researchers started looking into larger organisms, such as plants and goats. Nexia Biotechnologies is a Montrιal startup company that is making synthetic spider silk in genetically altered goats. A paper joint paper published in January 2003 by Nexia and U.S. military researchers announced the successful production of spider silk fibre in goats. The company is partially funded by the Canadian and American military. The science behind synthetic silk Scientists at Nexia started with spider silk genes that had been isolated by researchers from the University of Wyoming. "What we do is isolate the gland that actually produces the silk, types that we're looking for. Then we make a DNA library of all the genes that are actively being used by that gland," says Randy Lewis, from the department of molecular biology at the university. Since the major job of the gland is to make silk. Next, the DNA library is screened to find the spider silk gene. The gene is then sequenced to determine the code of the DNA. This code reveals the genetic instructions necessary to make the protein.

The isolated spider silk gene is then inserted into goat DNA in such a way that the spider silk protein is only made in the mammary glands of the animals. In other words, the gene is only expressed, or activated, in the milk-producing cells of the goats. Harold Hafs is chair of the department of animal sciences at Rutgers University. He is also on the science advisory board for Nexia, and on its board of directors. Hafs cites the convenience of using milk as a system because it has been studied by chemists in great detail for the past 50 years. "When they discovered that this would work in goats, it was truly a breakthrough. ...Nobody had ever done this sort of thing before," Hafs says.

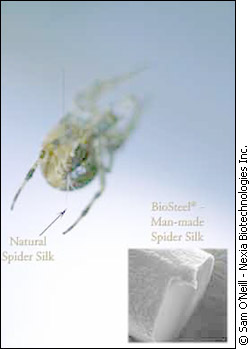

"And now they have goats that are happily producing milk with a gram or two of spider silk in every litre or so of their milk." How do they do it? This is all happening at Nexia's medically clean goat farm in Quebec, which has room for several hundred goats. The goats only make the protein. They can't spin it into webs. Here's what happens. After the goats are milked, the milk is put in a machine like a centrifuge, which spins the milk very fast. This causes the components in the milk to separate by weight. The fats and the creams are taken out of the milk at this point. The liquid that is left over contains a solution of the spider silk protein. By adding certain salts to the solution, the protein is precipitated (that is, it becomes solid), and can be filtered from the solution. The silk protein actually separates from the milk liquid quite readily because it is so different from the other normal proteins already in the milk. Next, the protein is dissolved in a water-based solution, and undergoes a process called "wet extrusion." The liquid containing the silk protein is forced through a very small opening, coming out in a little jet. The stream of liquid begins to harden in the presence of air, and is dipped in alcohol to further solidify the fibre and remove the water. The result is one continuous strand of spider silk, which is wound onto a bobbin. Nexia calls their synthetic spider silk 'BioSteel.'

Sam Hudson says it will be another year or two before Nexia starts commercial production. "Now we're working on grams per hour production, and we're working up to kilograms," he says. One of the first products Nexia plans to market is fly fishing line. The reasons for this are that the silk is biodegradable, very strong, very thin, and very sensitive. Also, the weaving process is still in initial research stage. "Every fibre has its own characteristics when you put it in a loom and you need to develop certain lubricants and figure out the relative humidity," Hudson continues. This is Hudson's area of expertise. He has worked with similar fibre systems since the 1980's, and is also one of Nexia's science advisors. Another of the applications Nexia is looking to market initially is opthalmological sutures. Stitches used in eye surgery need to be very fine and very strong. Hafs says that the demand for protein with these two products can be satisfied by the goats at the Quebec farm. However, once Nexia figures out how to weave the fibre, they will turn to the goats at their upstate New York farm. In the future... Eventually the weaving process will be developed, and Nexia can begin producing what the military is really interested in: body armour. Spider silk seems ideal for this application because of its high strength to weight ratio. It is stronger than steel by weight, more elastic than nylon (it can stretch to almost twice its original length without breaking), and is both lighter and stronger than kevlar. An issue with body armour is weight. Mobility cannot be sacrificed for padding. The lighter and stronger the material, the more useful. It is estimated that a strand of spider silk the thickness of a pencil can stop a Boeing 747 airplane. If production in goats is not enough, Nexia will begin research into producing the spider silk protein in cows, since cows produce a lot more milk than goats.

|

|

|

Nexia's

BioSteel spider silk Dr. Cheryl Hayashi's spider silk research All about spider silk |