It began with “the world’s best scalpel,”

a scalpel shaped like a carving knife but with the functional

capability of a retractable Exacto knife, according to Michael

Bell, a plastic surgeon at the Ottawa Hospital.

After years of research, development and a seven-figure

investment in the company, Bell and the company’s founder,

Leonard Lee, started making medical products and systems

they say are more successful than more conventional medical

devices.

|

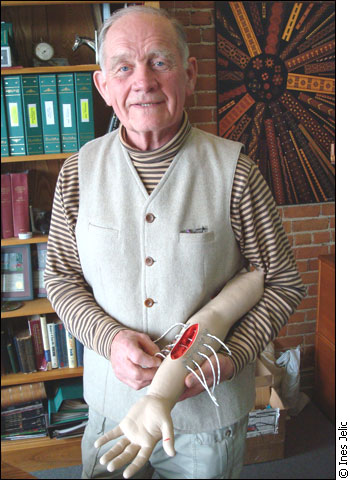

| Leonard Lee, age 71, has designed

some of the most innovative new medical products on the

market. |

“We have produced products that are stunningly good

at what they do,” says Lee.

Cutting edge technology

The focus of the designs is the manipulation of a patient’s

skin with the use of mechanical devices to facilitate complex

operations.

Probably the most innovative of Lee’s designs is the

dynamic wound closure system.

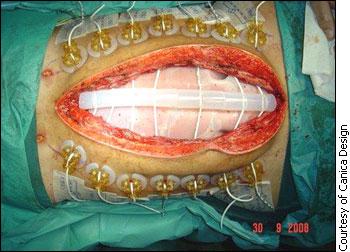

The system consists of one of three different types of anchors:

adhesive, skin and button. Different anchors are used depending

on the tension of the skin on either side of the wound. Elastic

silicone cords are fed through a wire cleat that is attached

to the anchors. The cord, which is called an elastomer, can

be laid over the skin or inserted through the skin like sutures

for better grip. The elastomers are labeled with black lines

to indicate the level of tension that is put on the wound.

The elastomers are tightened every three to four days until

the two sides of the incision meet and heal or are stitched

or stapled together. This process can be compared to tightening

a corset. The only difference is that while a corset uses

one string to connect all points, the wound closure system

uses an elastomer for every entry point on either side of

the wound.

| 'You can't measure

the value of being able to close an abdomen.' |

By attaching the anchors and using elastomers the surgeon

is able to slowly stretch the skin that retracts upon creating

an incision, and pull it together.

Previously, it would take two weeks to stabilize the wound

and one year to heal says Bell.

But, with the Canica system, it takes less than three days

to close a medium-sized incision.

Prior to this system, plastic surgeons would use tension

sutures, which were prone to ripping skin because of the

high tension of the retracted skin, or rely on skin grafts

to patch the open wound rather than closing it.

Bell says

that with old techniques “the

person is crippled with a chronic hernia.”

But, with the wound closure system, Bell says that “you

can’t measure the value of being able to close an open

abdomen. The patient walks out of the hospital without a

skin graft, without the need for another operation and without

a painful donor site.”

Canadian innovation vs. implementation

Despite the benefits, the problem facing Lee is the lack

of acceptance of his products by many surgeons, hospitals,

and the health care system.

|

Warning: Surgical photographs are graphic in nature. Viewer discretion is advised. |

Requires

FlashPlayer  |

|

Julia Barry, the manager of clinical and regulatory

affairs at Canica says that trying to convince people within

the health care system to incorporate their products is difficult.

She says despite extensive research and practical proof

in war zones of the efficacy of Canica products, the lack

of a drive towards accepting new technologies and systems

by surgeons is making it difficult to conduct proper and

objective research that would be accepted by the health care

system.

Lee admits he didn’t consider the difficulty in

trying to change the current practice in medicine.

He says that the health system and the hospital budgeting

structure make it difficult, because money cannot be transferred

between departments, or taken from equipment or patient

care costs.

The cost of the system would have to be paid by the department

where it is used, usually in the operating room, but the

benefits would only be visible in intensive and home care.

|

| Wound closure

systems manipulate the elasticity of the skin in order

to allow the closing of the wound with less scarring. |

But Bell explains that “you almost eliminate home

care, because the patient can walk out of the hospital with

this system on.”

At the Ottawa Hospital, Civic campus, surgeons using the

system estimated that the average patient cost saving where

a Canica device was used was $8,000, 10 times the cost of

the system itself.

Still, Lee says that the systems are not used continuously

in any other hospital in the city.

The American health care system on the other hand provides

monetary incentives for surgeons who use Canica products,

because of the cost savings. This is contrary to Canada,

where incentives are not given and surgeons are reluctant

to change their ways because of the extra training the new

technologies would require.

Lee and Bell agree that as young surgeons who are more welcoming

to change phase out their predecessors, Canica products will

catch on faster because they will become the norm.

For now, Canica Design research and development has halted,

but Lee and his team are working on getting their products

licensed so they can be used more widely in hospitals in

Canada and around the world.

Like any good medical device, Bell says, “it takes

time to catch on.”

|