|

| Two men install a solar panel on a roof. |

The Canadian conundrum surrounding renewable energy is that

manufacturers in Canada have to order most of their parts

from the U.S. and Europe. With all the energy used in shipping

parts - and sometimes whole units - across

oceans and down highways, should the 100-mile diet apply

to energy too?

Scientists use a calculation called Energy Pay Back Time

(EPBT) to rate the overall energy impact of a sustainable

energy source - how long it takes a panel or turbine

to produce as much energy as it took for it to be manufactured.

The average EPBT for a solar panel, according to Karl Knapp,

is about two to three years. For a wind turbine, he says,

it's about two to three months.

| 'We are only a few

players in the mid-sized market. The industry focuses

on the big (turbines).' |

Knapp was one of the American scientists studying the EPBT

of solar panels in the late 90s and early 2000s. Knapp says

he and his team tried to take everything into consideration ñ right

down to the energy used by pop machine in the plant where

they built the solar panels. The one thing his report says

they missed in their calculations, however, was the energy

used to bring parts to the plant and transport the final

product to the site where they are being used.

This might be the biggest factor in evaluating the efficiency

of solar panels and wind turbines in Canada.

Dirtier shades of green

Énergie PGE is a Quebec company that designs and

assembles the 35kW to 50kW turbines (mostly used on farms)

from its home-base in Saint-Jean-Port-Poli, about 100 km

east of Quebec City.

|

| Énergie Ressource Développement

uses mostly Canadian-made parts and assembles them in

its Quebec plant. |

While Énergie PGE makes its own blades on-site and

use towers manufactured in Toronto and Missauga, Marc-André Normandin, the sales and marketing director at Énergie

PGE, says the company gets air shipments of parts about once

a month from Germany and Italy and has pieces rolling in

on flat-bed trucks from the U.S. regularly.

Normandin says his company relies on imported parts because

no one in Canada makes the components they need.

"We are only a few players in the mid-sized market,"

he says. "The industry focuses on the big (turbines)."

Ivan Reyes tells a similar story. He works at Centennial

Solar, a Quebec company that has been manufacturing solar

panels since 2004.

The company gets their solar cells from Germany because

no one in Canada makes them. The solar cells are the 15-centimetre

by 15-centimetre-square silicon bits that fit together to

make the surface that captures energy from the sun.

"There isn't a high demand in Canada," Reyes

explains. Centennial Solar is one of two Canadian manufacturers

who make panels this particular size.

| 'It boils down to the

same question: do you buy fluorescent bulbs, even though

they have mercury?' |

But, there is one Canadian company keeping it local.

Made in Canada

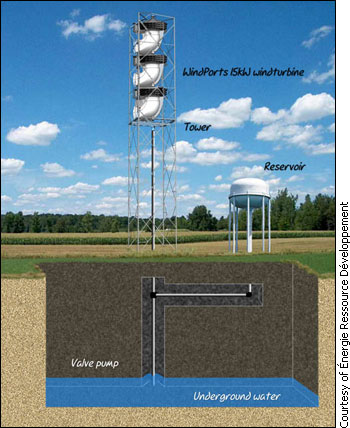

Énergie Ressource Développement (ERD) is an

anomaly. Instead of placing rotating blades on a stand-up

tower (think arms on a clock), wind gets caught in a horizontal

turbine (think record on a turntable) and flows down through

an L-shaped shaft.

The company also gets almost all of its parts in Quebec.

The company only purchases the generators for their systems

from abroad because they need to follow electrical codes

specific to the country where they are installing the turbine,

says Michel.

Regardless of how much energy is used in making solar panels

and wind turbines, Rock Radovan says people will still invest

in renewable energy.

People are still willing to take the "warts" of

renewable energy over nuclear and coal energy production,

says Radovan, the president of Sustainable Ottawa, a local

volunteer association encouraging a more environmentally-friendly

Ottawa.

"That trade-off depends on each individual person,"

says Radovan. Getting to make that decision "makes

people feel less helpless," he says.

"It boils down to the same question: do you

buy fluorescent bulbs, even though they have mercury?"

Frontpage photo courtesy of The Wild Center

|